Functional Properties

If you are looking for a protein to add to your baked goods, pastas, sausages, etc. , consider mealworm protein powder for the functionality it provides. The research on mealworm protein functionality is in its infancy, but is growing rapidly in interest. We found and summarized data from several researchers below. Hopefully, over the next couple of years we will have a larger database of information to pull from.

In most cases the data show a wide range of values. This is likely due (as noted by all the research articles this data pulls from) to the differences in rearing techniques, feedstock, and processing methods. Some methods, and rearing techniques are clear winners, however much more research needs to be done.

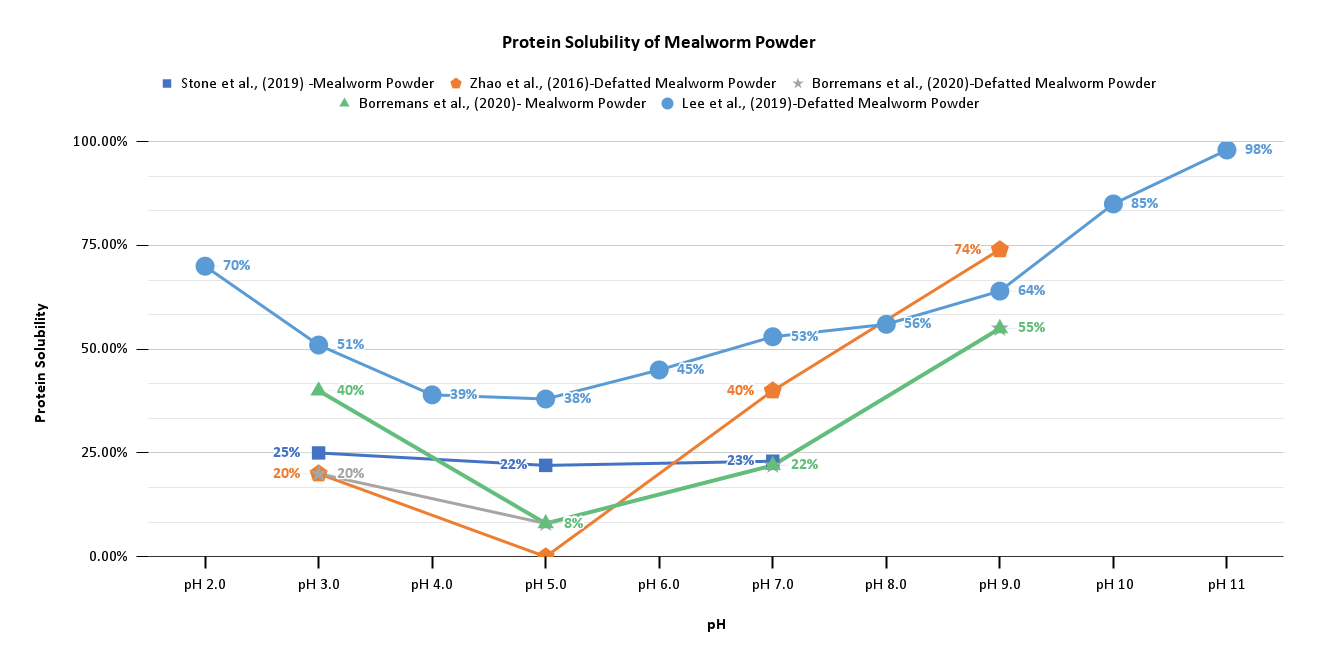

Solubility

We found a fair bit of research into the water solubility of mealworm proteins. As with a lot of the research, we noticed a broad range of data, making it challenging to draw conclusions.

Most of the researchers found low solubility at neutral pH and values over 50% at pH of 9 or higher. "Overall the insect powders are well suited for use as novel protein sources with more research needed into their applicability as ingredients in specific food products where high solubility is not a requirement such as extruded snack products, binders in meat products, nutrition/sports bars, and bakery products." - Stone et. al., (2019).

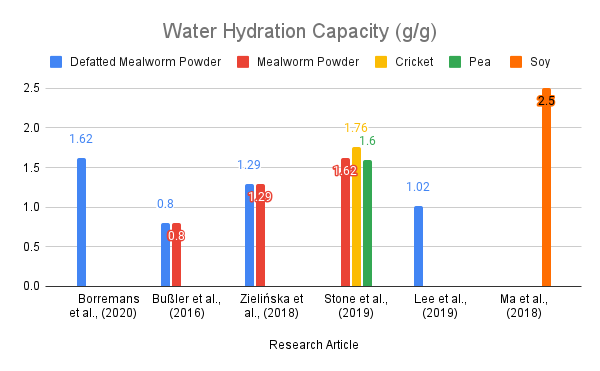

Water Hydration Capacity

According to Haque, et. al., (2016) "Water hydration capacity (WHC) is the ability of proteins to prevent water from being released or expelled from their three-dimensional structure. WHC plays an important role in developing food texture, especially in comminuted meat products and baked dough (Zayas, 1997b). Protein ingredients with very high WHC may dehydrate other ingredients in a food system. Proteins with low WHC can be more sensitive to storage humidity. Therefore, selection of proteins with an appropriate WHC is vital in food formulation."

Across six different researchers, we can see values between 0.8 (g/g) and 1.62 (g/g) for Water Hydration Capacity.

At Planet Bugs, we have yet to test our product for its WHC, but we expect it to fall within the ranges above, probably between 1.0 and 1.5.

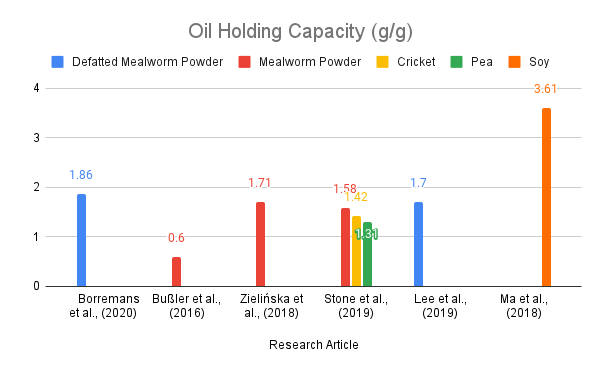

Oil Holding Capacity

According to Improve "Oil Holding Capacity corresponds to the amount of oil that a sample can absorb per unit of weight. An ingredient with high OHC can be used to improve the texture of a product. It can also be used to improve the juiciness of meat products after cooking"

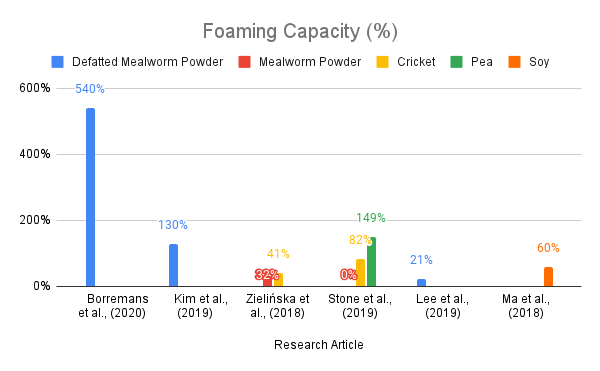

Foaming Capacity

According to Mauer, (2003) "the foaming capacity of a protein is measured as the amount of interfacial area that can be created by whipping the protein."

The bar graph really exmpelifies the vast range of foaming capacity of mealworms. Planet Bugs has not yet tested our Foaming capacity and there is a wide range of possibilites, all dependent on the method and heat used during the test.

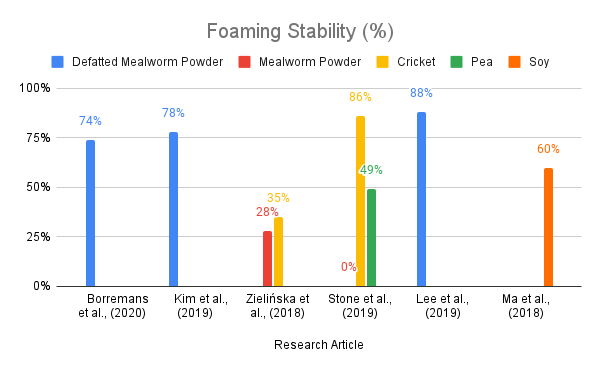

Foaming Stability

According to Mauer,(2003) "Foam stability is measured as the time required to lose either 50% of the liquid or 50% of the volume from the foam. Generally, heating a globular protein to achieve partial denaturation will increase foaming properties."

Planet Bugs has yet to test our Foaming Stability, however we would expect ours to be within the range of 74% to 88%.

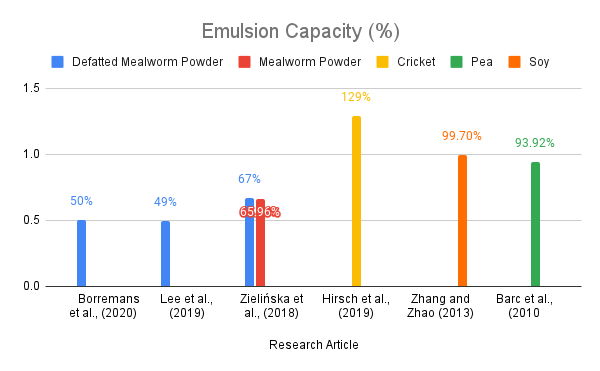

Emulsion Capacity

According to Bußler et al., (2016) "Emulsion capacity (EC) denotes the maximum amount of oil that can be emulsified under specified conditions by a unit weight of the protein." More simply put, the EC is a metric of the ability of the protein to emulsify within solution.

There is a wide range of emulsion capacities among different types of proteins depicted above. There are multiple ranges within these as well. Planet Bugs has yet to run our own Emulsion capacity, however we suspect ours to be within a range of 49% to 67%.

Emulsion Stability

According to Biolin Scientific, "Emulsion stability can be defined as the system’s ability to resist changes in its physicochemical properties over time. Emulsion stability is important in manyindustrial applications, including coatings, food products, agriculture formulations, personal care and petroleum." More simply put, the Emulsion stability is the ability for the protein to stay mixed with the solution and not separate out.

Again, there is a wide range of emulsion stability between different proteins, with many factors affecting the overall stability. Above are some examples from multiple research articles. Planet Bugs has yet to run our own Emulsion Stability tests, however we suspect ours to be within a range of 51% to 92%.

- Borremans, A., Bußler, S., Sagu, S. T., Rawel, H., Schlüter, O. K., & Leen, V. C. (2020). Effect of Blanching Plus Fermentation on Selected Functional Properties of Mealworm (Tenebrio molitor) Powders. Foods, 9(7), 917.

- Bußler, S., Rumpold, B. A., Jander, E., Rawel, H. M., & Schlüter, O. K. (2016). Recovery and techno-functionality of flours and proteins from two edible insect species: Meal worm (Tenebrio molitor) and black soldier fly (Hermetia illucens) larvae. Heliyon, 2(12), e00218.

- Hall, F. G., Jones, O. G., O’Haire, M. E., & Liceaga, A. M. (2017). Functional properties of tropical banded cricket (Gryllodes sigillatus) protein hydrolysates. Food Chemistry, 224, 414–422.

- Haque, Md. A., Timilsena, Y. P., & Adhikari, B. (2016). Food Proteins, Structure, and Function. In Reference Module in Food Science. Elsevier.

- Hirsch, A., Cho, Y.-H., Kim, Y. H. B., & Jones, O. G. (2019). Contributions of protein and milled chitin extracted from domestic cricket powder to emulsion stabilization. Current Research in Food Science, 1, 17–23.

- Kim, T.-K., Yong, H. I., Jeong, C. H., Han, S. G., Kim, Y.-B., Paik, H.-D., & Choi, Y.-S. (2019). Technical Functional Properties of Water- and Salt-soluble Proteins Extracted from Edible Insects. Food Science of Animal Resources, 39(4), 643–654.

- Lee, H., Kim, J., Ji, D., & Lee, C. (2019). Effects of Heating Time and Temperature on Functional Properties of Proteins of Yellow Mealworm Larvae (Tenebrio molitor L.). Food Science of Animal Resources, 39(2), 296–308.

- Ma, W., Qi, B., Sami, R., Jiang, L., Li, Y., & Wang, H. (2018). Conformational and Functional Properties of Soybean Proteins Produced by Extrusion-Hydrolysis Approach. International Journal of Analytical Chemistry, 2018, 9182508.

- Mauer, L. (2003). PROTEIN | Heat Treatment for Food Proteins. In B. Caballero (Ed.), Encyclopedia of Food Sciences and Nutrition (Second Edition) (pp. 4868–4872). Academic Press. https://doi.org/10.1016/B0-12-227055-X/00988-3

- Stone, A. K., Tanaka, T., & Nickerson, M. T. (2019). Protein quality and physicochemical properties of commercial cricket and mealworm powders. Journal of Food Science and Technology, 56(7), 3355–3363.

- Zhao, X., Vázquez-Gutiérrez, J. L., Johansson, D. P., Landberg, R., & Langton, M. (2016). Yellow Mealworm Protein for Food Purposes—Extraction and Functional Properties. PLoS ONE, 11(2).

- Zhang, Y.-N., & Zhao, X.-H. (2013). Study on the Functional Properties of Soybean Protein Isolate Cross-Linked with Gelatin by Microbial Transglutaminase. International Journal of Food Properties, 16(6), 1257–1270.

- Zielińska, E., Karaś, M., & Baraniak, B. (2018). Comparison of functional properties of edible insects and protein preparations thereof. LWT, 91, 168–174.

- Improve-innov.com

- Biolin Scientific